In the production process of the painting workshop, the organic waste gas generated by the drying furnace needs to be incinerated and purified before it can be discharged. This incineration process produces high-temperature exhaust gas, and the waste heat from this high-temperature exhaust gas can be recovered and reused. In this context, adding a waste heat recovery system for RTO high-temperature exhaust gas can help customers fully utilize this heat energy, reduce production costs, and improve energy efficiency.

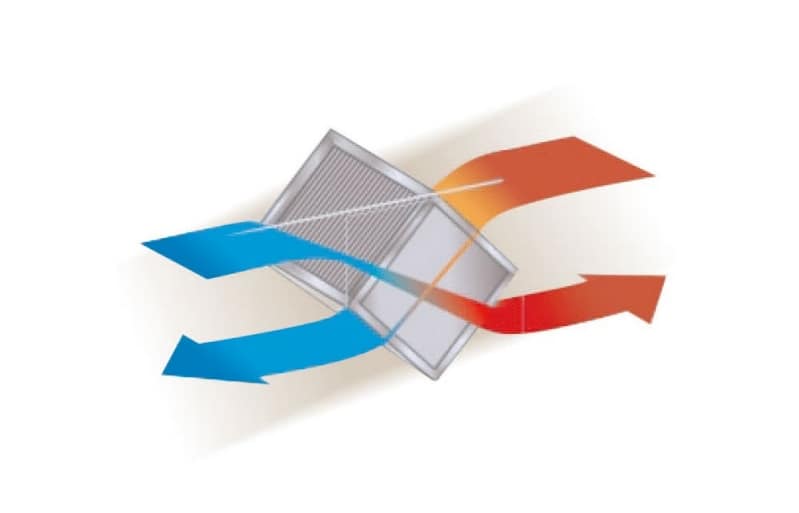

The main component of the waste heat recovery system is the cross flow heat exchanger (BXB plate heat exchanger), which is mainly made of stainless steel foil. Two streams of air separated by stainless steel foil and flowing in opposite directions will transfer heat when there is a temperature difference, achieving energy recovery. By using a cross flow heat exchanger, the heat in the exhaust can be utilized to preheat the fresh air, thereby achieving the goal of energy conservation.