Aluminum foil is often used in the manufacture of heat exchangers due to its excellent physical and chemical properties, especially in applications that are lightweight and efficient in heat transfer. The following are its main characteristics:

High thermal conductivity: The thermal conductivity of aluminum is about 237 W/(m · K), which can quickly transfer heat and improve heat transfer efficiency.

Lightweight: Aluminum foil has a low density (about 2.7 g/cm ³), reducing the overall weight of the heat exchanger and facilitating installation and maintenance.

Corrosion resistance: The naturally formed oxide layer (Al ₂ O3) on the surface of aluminum has a certain degree of corrosion resistance and is suitable for humid environments, but requires additional protection under strong acid-base or high salt conditions.

Strong processability: Aluminum foil is easy to shape and can be made into thin sheets or complex structures (such as corrugated shapes), increasing the heat transfer area.

Cost effectiveness: Compared to copper and other materials, aluminum foil has a lower price and is suitable for large-scale applications.

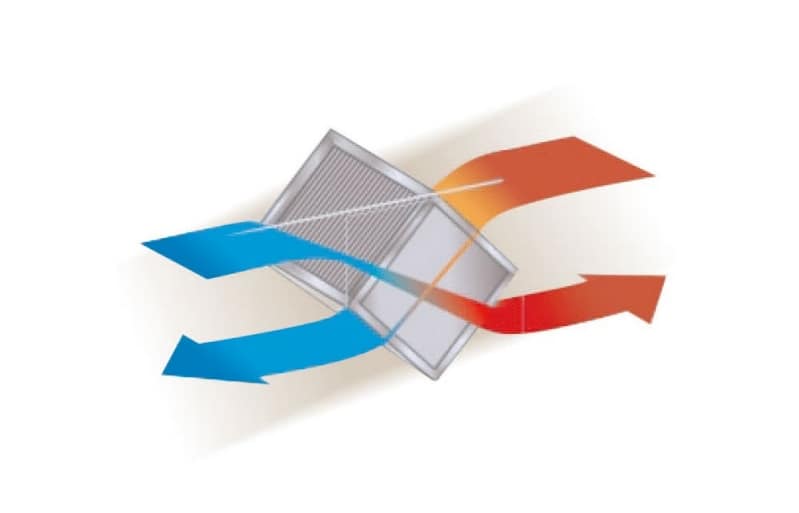

In cross flow gas air heat exchangers, aluminum foil is often made into fins or microchannel structures to increase the heat transfer area and optimize the airflow distribution.