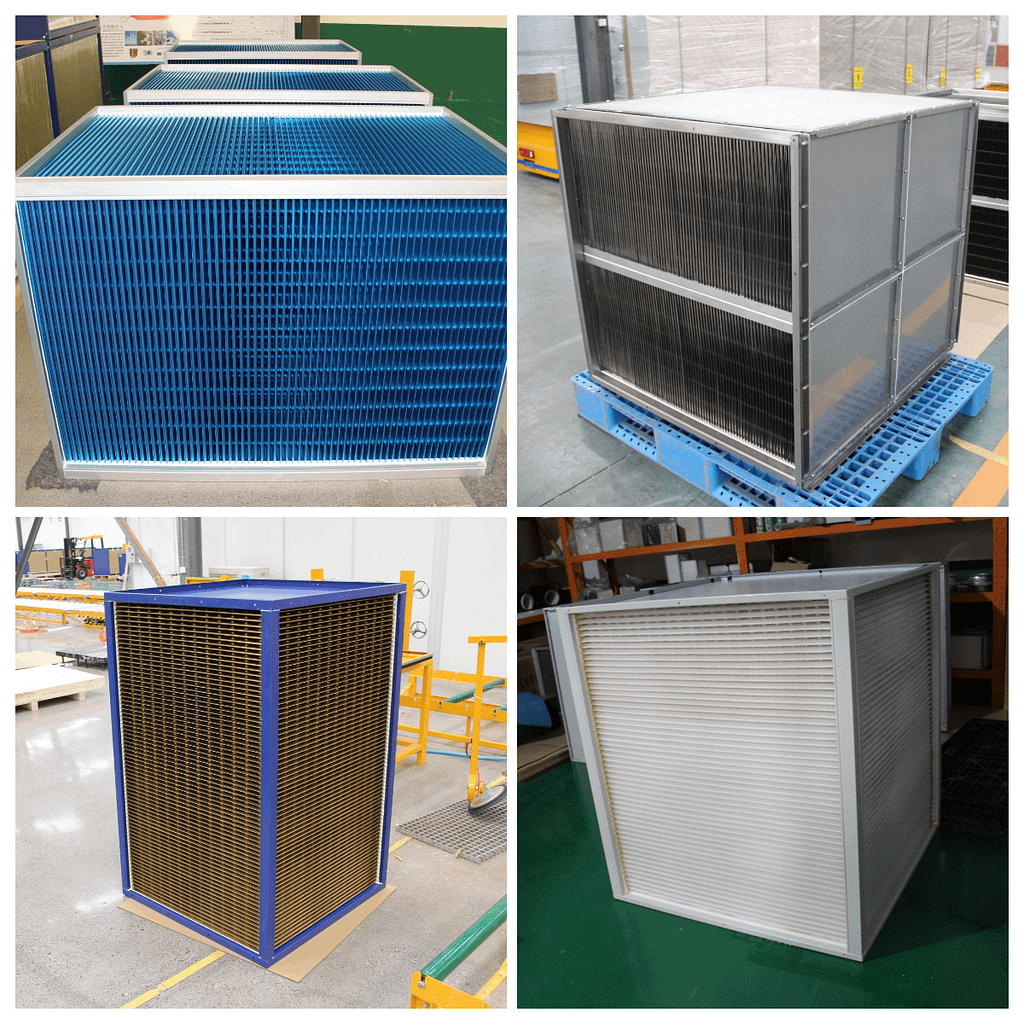

Stainless steel foil/hydrophilic aluminum foil/epoxy aluminum foil/polymer PP

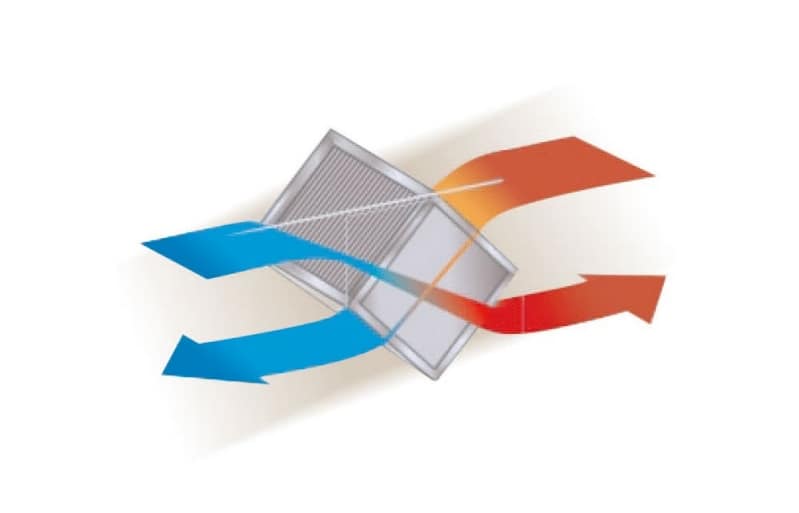

Structural characteristics of

·BXB sensible heat exchanger can be made of seawater corrosion resistant hydrophilic aluminum plate, epoxy resin aluminum plate or stainless steel plate;

· The heat transfer surface of the heat exchanger was strengthened by heat transfer stamping, and the heat transfer area was increased by 10%-12%;

· The heat exchange sheet adopts enhanced punching and biting technology, with higher strength, better sealing, and air leakage rate less than 1%;

· The air passage is supported by a conductor convex cylinder with a high pressure difference capacity of 2500Pa for new exhaust;

· The normal service temperature of ordinary aluminum foil is not higher than 100℃; the temperature resistance of special sealing material can be up to 200℃; the temperature resistance of stainless steel can be 350℃;

· Tap water or neutral washing liquid can be used for direct cleaning, which is easy to use and easy to maintain;

· Different plate spacing (2.0mm-10.0mm) and any combination length can be provided.

application

·AC Ventilation System

·Room Ventilation System

·Industrial Ventilation System

·Heat Pump Drying System

·Indirect Evaporative Cooling System

·Large-scale Scientific Breeding Bystem

·Purify Air Conditioning Fresh Air System

·Wind Generator Air to Air Indirect Cooling System

·Heat Recovery in Winter

·Cold Recovery in Summer