A rotary heat exchanger (also known as a rotary wheel or thermal wheel) operates on the principle of heat transfer by using a rotating wheel to exchange energy between two air streams, typically supply and exhaust air. It is widely used for energy recovery in HVAC systems, industrial processes, and other applications. Below is an explanation of its working principle:

Components of a Rotary Heat Exchanger

- Rotating Wheel (Rotor): A circular wheel made of aluminum or other thermally conductive material. The wheel is often coated for specific purposes, such as moisture transfer.

- Drive Mechanism: A motor-driven system rotates the wheel slowly (typically 10–20 RPM).

- Supply Air Stream: Fresh air entering the system, typically from outside.

- Exhaust Air Stream: Stale air exiting the system, carrying heat or moisture.

Working Process

- Two Air Streams:

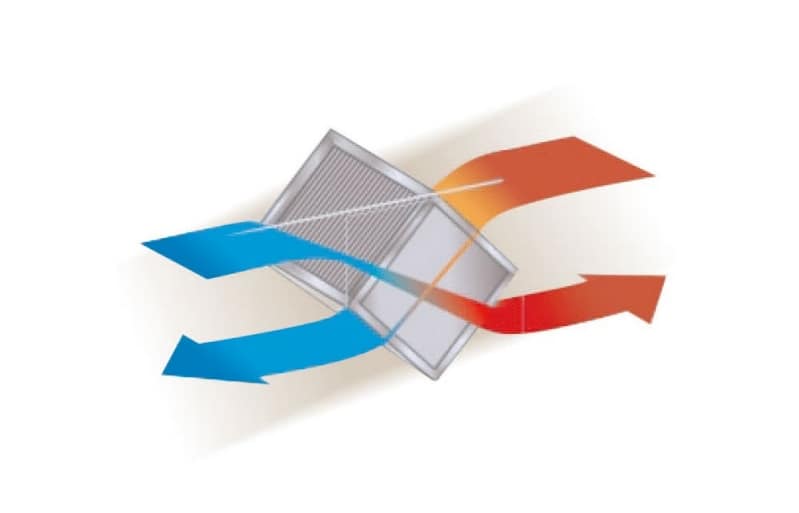

- The rotary wheel is placed between the supply air stream (cold/fresh air) and the exhaust air stream (warm/stale air).

- These two streams flow through separate sections of the wheel without mixing directly.

- Heat Transfer:

- As the wheel rotates, the part of the wheel exposed to the exhaust air stream absorbs heat (thermal energy) from the warm air.

- When this portion of the wheel rotates into the supply air stream, the stored heat is transferred to the colder supply air.

- Moisture (Latent Heat) Transfer(Optional):

- In wheels with hygroscopic coatings, moisture from the humid exhaust air is also absorbed by the wheel.

- When the wheel moves into the dry supply air stream, the absorbed moisture is released, transferring latent heat.

- Continuous Rotation:

- The wheel rotates continuously, ensuring a constant exchange of heat (and moisture, if applicable) between the two air streams.

Types of Energy Recovery

- Sensible Heat Recovery:

- Only heat (temperature difference) is transferred between the air streams.

- Example: Cooling or heating the supply air.

- Total Heat Recovery (Sensible + Latent Heat):

- Heat and moisture are transferred, enhancing efficiency.

- Example: Humidity control in buildings.

Key Advantages

- Energy Efficiency: Reduces heating or cooling loads by recovering up to 70-90% of energy from the exhaust air.

- Cost Savings: Decreases energy consumption, resulting in lower operating costs.

- Compact Design: High heat transfer rates with a relatively small footprint.

- Customizable: Can be tailored for specific applications with coatings for moisture transfer or corrosion resistance.

Applications

- HVAC Systems: Used in ventilation systems for commercial and residential buildings to improve energy efficiency.

- Industrial Processes: Applied in drying, food processing, and chemical industries.

- Moisture Management: Maintains indoor air quality and desired humidity levels in controlled environments.

In summary, rotary heat exchangers efficiently recover and reuse energy from exhaust air to pre-condition incoming air, reducing energy consumption and improving sustainability in various applications.